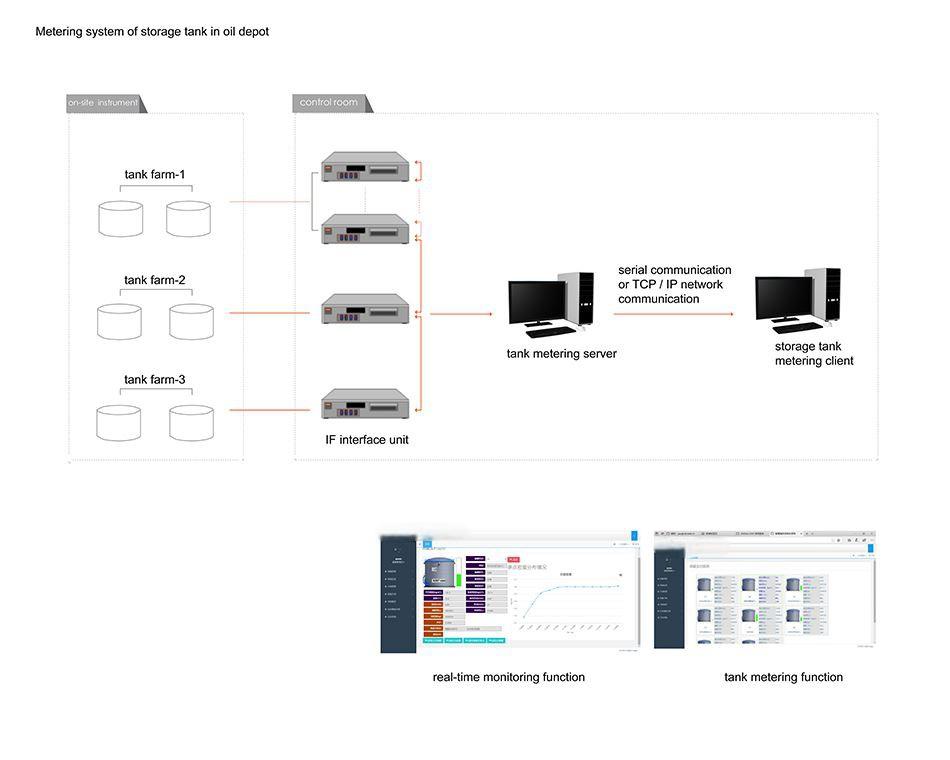

The storage tank metering system is based on the online data of the storage tank, combined with the dynamic model of the storage tank, and automatically calculates the information of the medium temperature distribution, density distribution, inventory, and transfer volume. Non-destructive reading of measured values is achieved through field bus instruments. The system has real-time monitoring, storage tank metering, custody transfer metering, inventory management, data correction, equipment diagnosis and other functions.

Characteristics & Advantages

——Fully automatic metering:

It can automatically calculate the sight volume, standard volume and weight based on real-time liquid level, temperature, density and other data, and automatically form a metering list.

——Digital storage tank model:

Based on the virtual digital storage tank model, automatic measurement data is calibrated in real time according to ambient temperature, sunshine, and storage tank life cycle.

——Data analysis:

Inventory volume / quality / standard body calculation analysis, breathing loss analysis, etc.

——Open interface:

The unified platform supports the communication protocols of all mainstream liquid level gauge manufacturers, and supports the access of various types of liquid level gauges such as servo lever gauge, hysteresis level gauge, radar level gauge, and differential pressure level gauge.

——Intelligent alarm and diagnosis:

In addition to the conventional high and low liquid level alarms, it also has data abnormality identification, leak analysis alarm, and instrument self-diagnosis alarm.

——-Multi-dimensional data recording and query:

Oil product change records such as the time and quantity of tank entry, storage, tank exit.

Change trend of liquid level, density, temperature can be recorded and checked.