The automatic loading system of oil depot provides customers with intelligent solutions for self-service unattended in the whole process of storage, loading and out of storage.

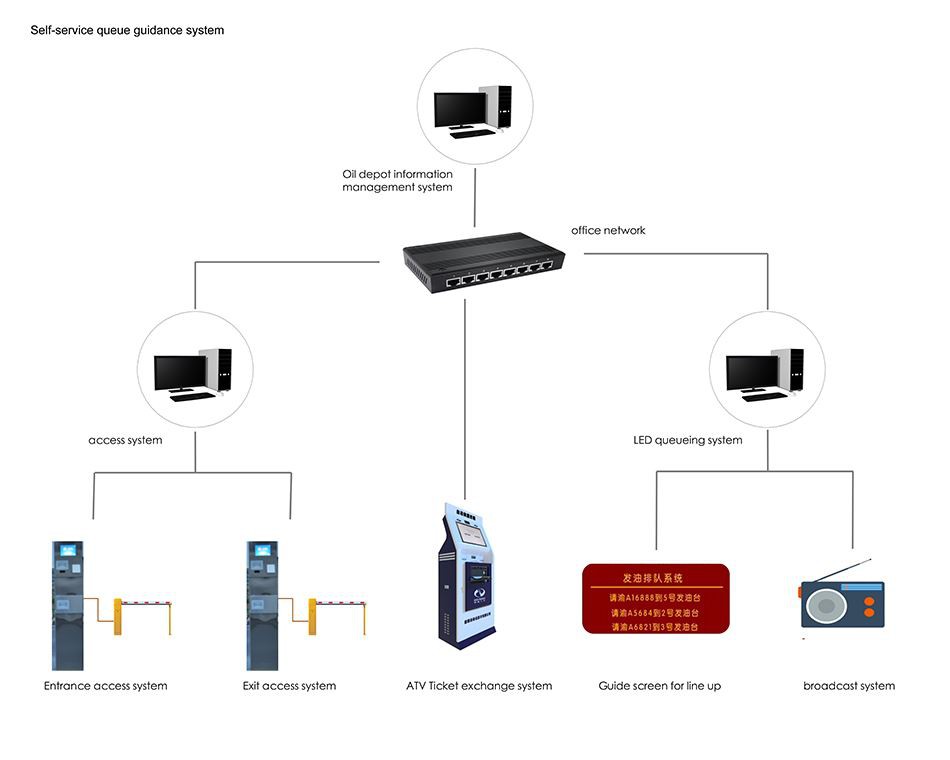

The self-service queuing guidance system automatically queues the vehicles according to the vehicle queuing situation and loading jack allocation, and prompts through LED large screens, displays, sounds and other equipment to guide the vehicles to enter and leave the oil depot in an orderly manner. The personnel entering the oil depot can perform self-service ticket exchange through the terminal.

The security inspection system confirms, inspects, and assesses the identification information, dressing conditions, and safety knowledge of personnel, and helps users standardize management of personnel entrance.

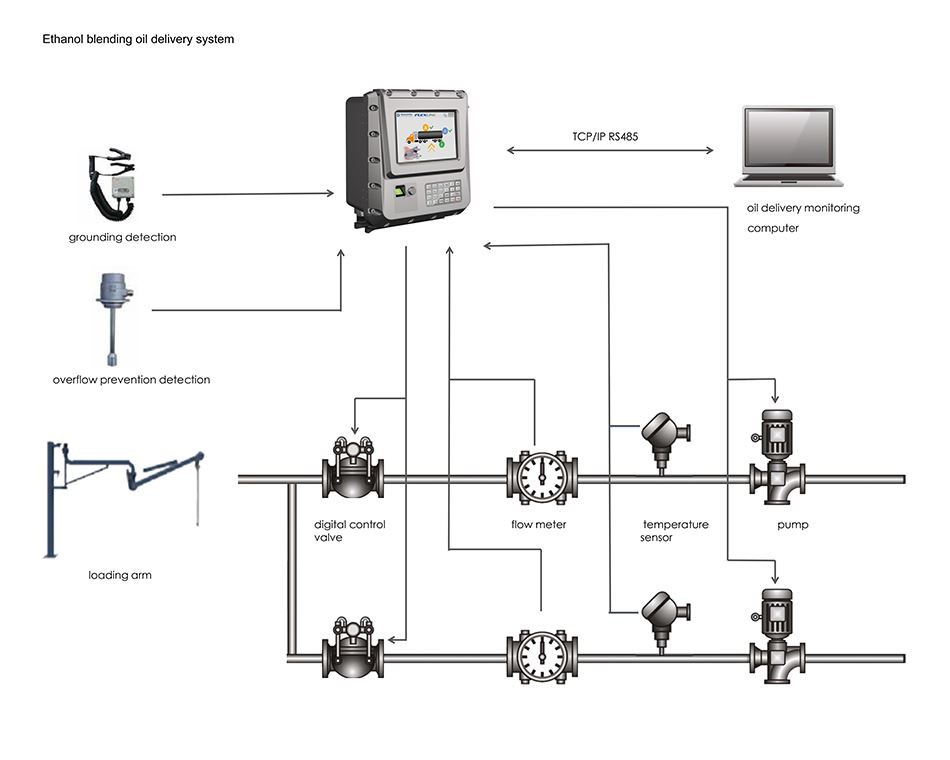

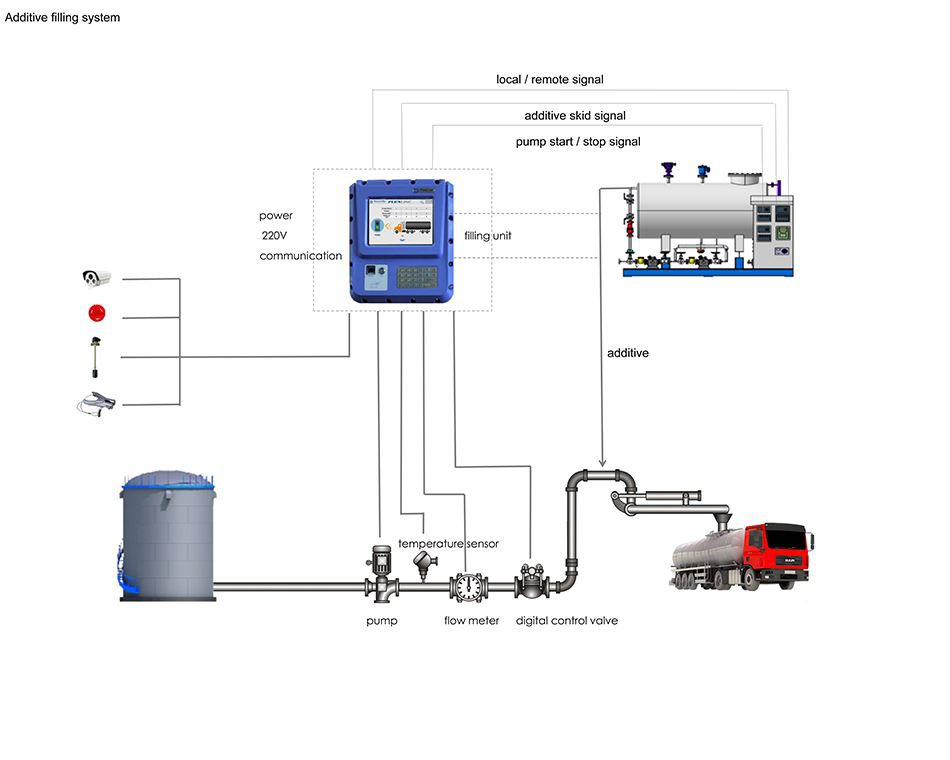

The intelligent ration output control system uses JSK-2012 ration controller as the on-site controller. By collecting on-site instrument data such as flow meters and temperature transmitters, and controlling on-site equipment such as valves and pumps, it realizes the distributed control of receiving and sending materials The type data management machine realizes the centralized management of sending and receiving materials in the warehouse area. At the same time, it supports the automatic addition and distribution of liquids such as ethanol and additives.

Characteristics & Advantages

—–Decentralized control and centralized management.

Each batch controller runs independently without affecting each other; the entire system is monitored and managed centrally.

—–Good openness.

It can be flexibly connected with systems such as card access control, ERP, self-service ticket exchange, queuing, position identification, electronic seal, automatic meter reading and other systems.

—–Comprehensive security management:

Hierarchical authority management of password and IC card.

Interlocking protection measures for static electricity overflow, overspeed, blockage, timeout, abnormal temperature and temperature, crane position, tank identification, car stopper, car key, human body static elimination.

—–System self-diagnosis for batch controller status, flow pulse diagnosis, digital control valve action sensitivity, abnormal temperature change, abnormal flow rate fluctuation, etc

—–Applications for various working conditions:

It is suitable for various liquid products loading such as refined oil, chemical products, LNG, edible oil, alcohol, etc.

It can be used for online blending, additive filling,and visual body, quality, standard body material delivery.

—–Precise control:

It supports temperature and density real-time compensation of national standard and API standard, adopts adaptive control algorithm and valve intelligent adjustment strategy, and has small batch control error and stable control.